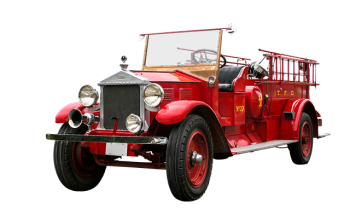

Brownsville fleet truck suspension repair is paramount for vehicle safety and operational efficiency. Rotors, critical components, facilitate braking and enhance stability. Regular inspection, preventative maintenance, and advanced diagnostics are key strategies to minimize downtime and costly repairs. Trained technicians and detailed records ensure accurate solutions, reliable operations, and informed decision-making for Brownsville fleet managers.

“Unleashing the power of understanding: Rotors as the backbone of your Brownsville fleet’s performance. This comprehensive guide delves into the intricate world of truck suspension, focusing on rotors—essential components ensuring smooth and safe rides. We explore common challenges faced by Brownsville fleet managers, from diagnosis to efficient repair strategies. Learn how identifying and addressing rotor issues can revolutionize your fleet maintenance routine, ultimately enhancing overall vehicle performance and longevity.”

- Understanding Rotors: The Basic Components of Truck Suspension

- Brownsville Fleet: Challenges and Solutions in Truck Maintenance

- Diagnosing Rotor Issues: Common Problems and Repair Techniques

- Efficient Repair Strategies for Optimal Fleet Performance

Understanding Rotors: The Basic Components of Truck Suspension

Rotors are fundamental components of a truck’s suspension system, playing a crucial role in maintaining optimal vehicle performance and safety. In the context of a Brownsville fleet, understanding rotor functionality is essential for efficient truck suspension repair and overall vehicle management. These disc-shaped parts are located between the brake pads and serve as the primary contact points for the pad’s friction material during braking.

As part of the braking system, rotors not only help in slowing down the vehicle but also contribute to its stability and handling. In Brownsville fleet operations, where trucks often navigate diverse road conditions, healthy rotors ensure consistent braking power and reduced wear, extending the life of the entire suspension and brake components. Regular inspection and maintenance of these basic suspension components can significantly impact the overall efficiency and safety of the vehicles in a fleet.

Brownsville Fleet: Challenges and Solutions in Truck Maintenance

Brownsville Fleet faces unique challenges when it comes to truck maintenance, particularly in the realm of suspension repairs. Operating a bustling fleet requires consistent and reliable vehicles, yet the constant wear and tear faced by these trucks in their daily tasks can lead to intricate suspension issues. From worn-out shocks to damaged springs, these problems not only impact the safety of the drivers but also disrupt the fleet’s operations and increase maintenance costs.

To address these challenges, a comprehensive approach is essential. Regular preventative maintenance checks can identify potential suspension issues early on. Moreover, investing in specialized equipment for accurate diagnostics and repairs, such as advanced shock testers and spring analyzers, enables efficient troubleshooting. Additionally, training mechanics on the unique features of Brownsville Fleet’s truck suspension systems ensures quick and effective solutions, minimizing downtime and keeping the fleet on the road.

Diagnosing Rotor Issues: Common Problems and Repair Techniques

Diagnosing rotor issues in a Brownsville fleet of trucks requires understanding common problems and their repair techniques, especially for those involved in heavy-duty vehicle suspension repairs. One of the most frequent rotor problems is wear and tear due to constant braking. This can lead to reduced thickness or even cracking, affecting the truck’s stopping power. Visual inspection and comparing rotors with known good conditions can help identify these issues early on.

Repairs typically involve replacing worn-out rotors, which may require specialized machinery to ensure new rotors are precisely machined to fit the vehicle’s suspension system. In some cases, rotor resurfacing or grinding is an option for minor wear, extending their lifespan. Proper diagnosis and timely intervention in Brownsville fleet truck suspension repair can prevent more severe damage and maintain optimal vehicle performance.

Efficient Repair Strategies for Optimal Fleet Performance

In the dynamic world of transportation, maintaining optimal fleet performance is key to success, especially for businesses like those in Brownsville focusing on truck suspension repairs. Efficient repair strategies are not just about fixing issues; they’re a strategic investment in fleet longevity and cost-effectiveness. By prioritizing proactive maintenance and utilizing advanced diagnostic tools, fleet managers can minimize downtime and reduce the need for costly emergency repairs. Regular inspections, including comprehensive checks of suspension components, tires, and brakes, are essential to identifying potential problems early on.

Brownsville fleet operators should also consider implementing a structured repair process that involves specialized technicians trained in modern truck suspension systems. This ensures that repairs are not just quick but also accurate, preventing further damage or wear. Additionally, keeping detailed records of maintenance and repair history enables managers to track trends, identify recurring issues, and make informed decisions about when to replace parts or overhaul entire systems. Such strategic approaches to truck suspension repair directly contribute to enhanced fleet safety, reliability, and overall operational efficiency.

Rotors play a vital role in truck suspension systems, impacting overall vehicle performance. For fleets like Brownsville, understanding rotor functionality and common issues is essential for efficient maintenance. By mastering rotor diagnosis and implementing effective repair strategies, fleet managers can ensure optimal performance, reduce downtime, and enhance safety on the road. This comprehensive approach to truck suspension repair, focusing on rotors, is a game-changer in maintaining a robust and reliable fleet.